Pour the stripping solution on the floor area and smudge it across it evenly with the brush.

Best floor marking strip.

If this is the first time you re stripping a hardwood floor it s best if you start out by testing on a smaller area somewhere in a corner.

How to strip hardwood floors.

48 inch long strips allow you to easily keep lines straight.

Brady toughstripe floor marking tape is made of rugged polyester material with ultra aggressive adhesive.

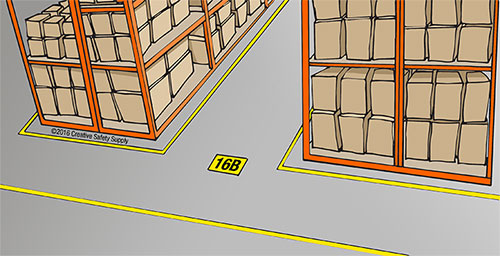

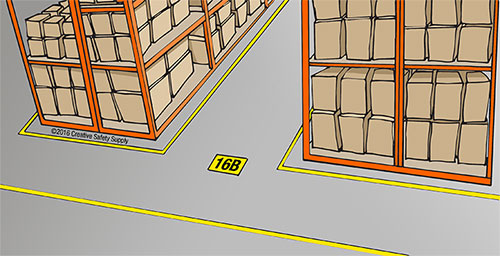

Visible floor marking improves safety and organization in almost any industrial environment.

Choose from our selection of solid floor marking tape striped floor marking tape 3m 471 solid floor marking tape and more.

Many companies use paint to mark out the shop floor and for many years it was generally the best solution available.

5s floor marking.

Applies and bonds easily to a variety of clean sealed and non coated surfaces.

In stock and ready to ship.

In many cases however people have already used the paint so doing all you can to get the most out of it is always a good idea.

Extremely durable toughstripe floor marking tapes are made of rugged polyester with ultra aggressive adhesive and hold up against forklift traffic.

Tough mark allows you to create highly visible pathways for forklifts and employees.

5s the lean manufacturing practice that aims to keep the workplace organized clean safe and efficient benefits from the use of floor markings too.

A standardized floor marking color system helps employees associate certain colors with certain areas or actions.

Marking striped lines on warehouse or production floors is useful for organization and clear layout it is also required for safety aisles and other osha reasons.

Related polishing hardwood floors.

Of course whenever possible it is best to use floor marking tape rather than floor marking paint.

High gloss surface shines like new paint and withstands forklift traffic without tearing or lifting.

Strips are made with 55 mil thick polyethylene with 9 4 mil thick polypropylene adhesive backing.

Strips are easily trimmed to needed length or to create corners.

However an expanded floor marking system that incorporates lean 5s and visual workplace concepts as well as standardizes color coding can improve both safety and efficiency.

It can be utilized to meet many different facility needs including marking safe passageways identifying inventory locations and alerting employees of hazardous equipment.

5s which stands for sort set in order shine standardize and sustain relies heavily on the use of visuals to communicate basic information about organizing and maintaining the workspace.